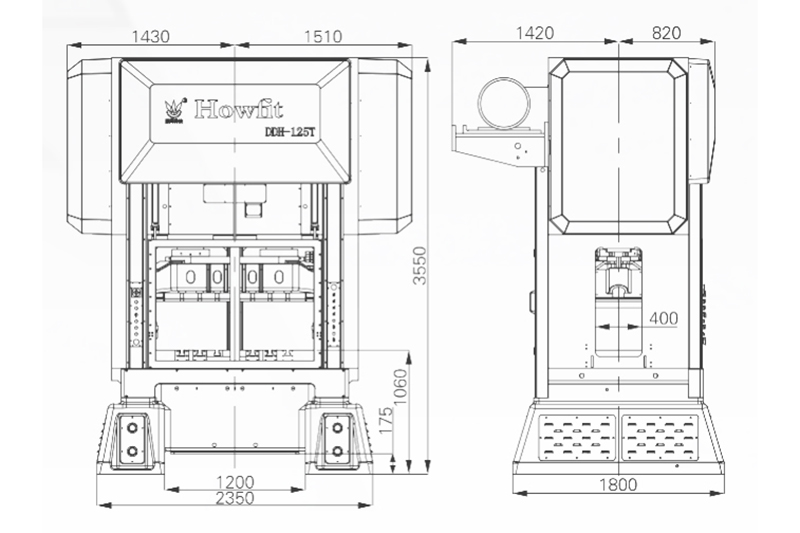

| Model | DDH-125T | |

| Capacity | KN | 1250 |

| Stroke length | MM | 30 |

| Maximum SPM | SPM | 700 |

| Minimum SPM | SPM | 150 |

| Die height | MM | 360-410 |

| Die height adjustment | MM | 50 |

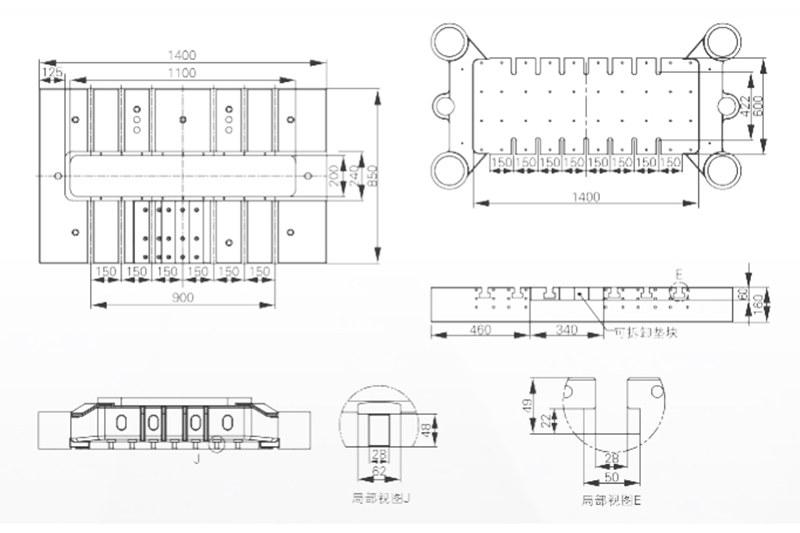

| Slider area | MM | 1400x600 |

| Bolster area | MM | 1400x850 |

| Bed opening | MM | 1100x300 |

| Bolster opening | MM | 1100x200 |

| Main motor | KW | 37x4P |

| Accuracy |

| Super JIS /JIS Special grade |

| Total Weight | TON | 27 |

♦ The frame is made of high strength cast iron, which eliminates the internal stress of the workpiece through natural long time after precise temperature control and tempering, so that the performance of the workpiece of the frame reaches the best state. ♦ The connection of the bed frame is fastened by the Tie Rod and the hydraulic power is used to prepress the frame structure and greatly improve the rigidity of the frame. ♦ Powerful and sensitive separation clutch and brake ensure precise positioning and sensitive braking. ♦ Excellent dynamic balance design, minimize vibration and noise, and ensure the life of the die. ♦ Crankshaft adopts NiCrMO alloy steel, after heat treatment, grinding and other precision machining.

♦ The frame is made of high strength cast iron, which eliminates the internal stress of the workpiece through natural long time after precise temperature control and tempering, so that the performance of the workpiece of the frame reaches the best state. ♦ The connection of the bed frame is fastened by the Tie Rod and the hydraulic power is used to prepress the frame structure and greatly improve the rigidity of the frame. ♦ Powerful and sensitive separation clutch and brake ensure precise positioning and sensitive braking. ♦ Excellent dynamic balance design, minimize vibration and noise, and ensure the life of the die. ♦ Crankshaft adopts NiCrMO alloy steel, after heat treatment, grinding and other precision machining.